Drying Solutions

The presence of moisture in packaged food products can cause growth of mold, microbes, or fungus, and hamper the stability of the product. Drying is a vital process in increasing the shelf life of any food product. Enhance the flow properties of powders, decrease bulk for transportation and ease handling, adequate and complete drying is important. Choice of the appropriate drying equipment and method is dependent on the type of material, its heat sensitivity and expected output.

Solar Dryers

Using an array of evolving technologies, solar energy is harnessed from the Sun and used for heating, refinement, drying, generating energy, artificial photosynthesis etc. Drying is a very important process to get dried products that are rich in fibre and carbohydrates and have a longer life. For these reasons and more, solar drying systems are gaining momentum across businesses for their efficiency and usefulness. However, even today, in few rural areas and traditional industries drying is done by putting the product out in the sun.

At Jaivik, we harness solar energy sustainably to power our solar drying system. By heating up air, the product is dried to ensure that the moisture is reduced, the quality is retained and the product’s shelf life is improved. The drying of agricultural products is a norm in the food processing industry that requires optimum drying for preservation, long-term storing and exports.

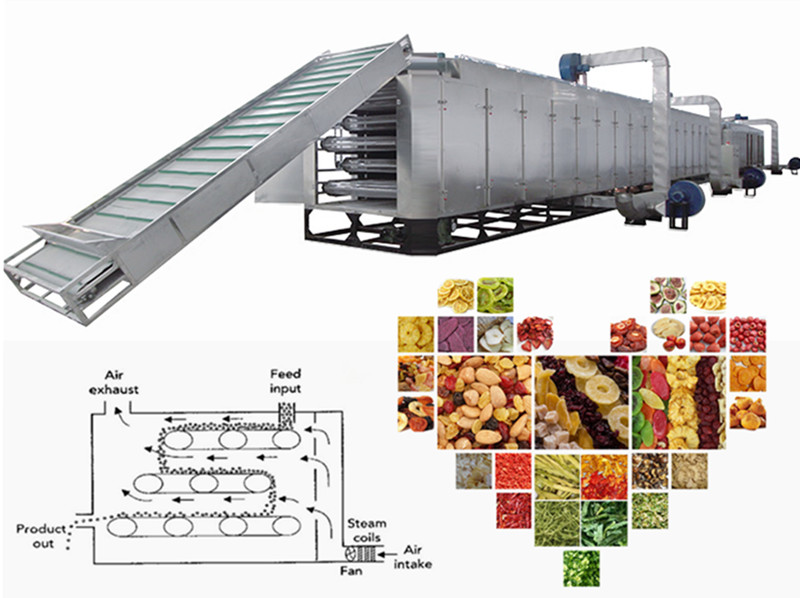

Belt Dryers

Belt dryers use air to dry food that is spread as a thin sheet on a horizontal lattice or solid belt. As the air passes through or over the material, it is properly dried. The hot air current circulating across the belts removes the moisture of the product through conduction. Apt for an extensive range of food products and suitable for continuous drying and cooling applications, belt dryers are ideal for small production rates.

Belt dryers employ heated air or an inert drying gas to get rid of the moisture. As the product passes through a drying chamber, placed on a perforated belt, it is dried out. Belt dryers are customizable to the needs of the industries and are great for manufacturing pelletized or granulated, dehydrated bulk products.

Vacuum Dryer

Heat-sensitive materials such as pharmaceutical active constituents, fine chemicals, and food products can be damaged by conventional drying processes. For these products, vacuum dryers help reduce the risk to the minimum by retaining the integrity of the product. In vacuum during, the pressure in the drying chamber is reduced in order to decrease the boiling point of the liquid in the substance. A significant decrease in boiling point intensifies the rate of evaporation of the liquid. Thus, allowing its removal from the solid.

While vacuum dryers are great for brittle and heat-sensitive materials, the choice of an appropriate vacuum dryer is guided by the types of the product, the amount of moisture to be eliminated and the required physical form of the end product.