Sterilization / Pasteurization

Microbial Safety in Spices, herbs, seeds and nuts

The world is changing; Consumers Want Healthy Foods which are not treated with a process that possible leave behind a chemical residue or create toxins. Jaivik Foods offers the following solutions for the same.

- Steam Sterilization

- Pasteurization

- Fluid Bed Dryers

- Sterilization

- Pasteurization

- Fluid Bed Dryers

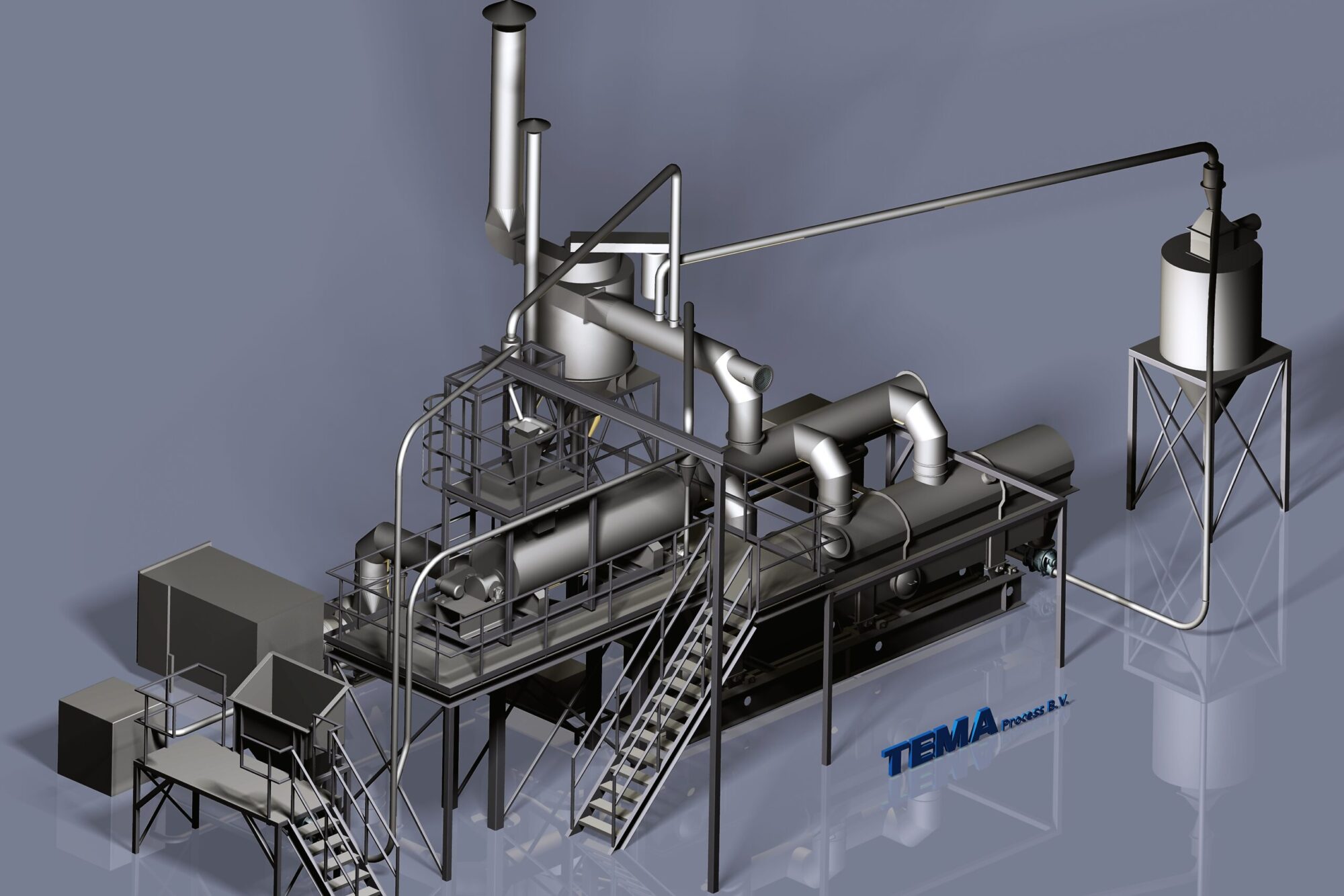

source: Tema process website

Sterilization

A diverse infectious bacteria reduction has become a huge bottleneck for the food industry. To overcome the same there are many practices employed, few include: fumigants (ethylene oxide and propylene oxide), steam and irradiation. Each method has its own advantages and limitations in effectiveness, quality impact and consumer acceptance.

We at Jaivik adapt the highly effective method of natural sterilization using pure steam through the introduction of the continuous HT-ST “In-Flow” steam decontamination process.

A very short contact (20-40 seconds) with high pressure steam at a temperature that may vary between 102°C and 122°C makes it possible to decontaminate heat sensitive herbs, pulses and spices without any adverse effect on quality. Our equipment consists of a special continuous autoclave with a so-called shaking bed conveyor and self-cleaning rotary valves for respectively product feed into and out of the pressure vessel.

The process is further identified by a sanitary fluid bed dryer/cooler, using sterile filtered air to bring the moisture content of the treated product accurately to the desired final moisture content.

Automatic cleaning in place (C.I.P.) provides for quick change from one product to another. The total process takes only 30 seconds for sterilization plus 7 minutes for conditioning. With the continuous process the product will not be subjected to a temperature above 55 degree C, longer than 60 seconds.

We develop the best machines, build them, test them, install them at your site and deliver support/spare parts.

Suitable for spices, herbs, botanicals, seeds, whole products and ground products.

source: Tema process website

source: Tema process website

Pasteurization

Vegetables are an important nutrient for a balanced and healthy diet; they provide essential vitamins, minerals, and dietary fiber for our bodies. However, vegetables are highly perishable and need appropriate preservation technologies to prolong their shelf life while maintaining nutritional and sensory qualities.

Pasteurization refers to heat treatment of food (usually below 100 deg C) we use natural steam with temperature between 100 -105 deg C to destroy microorganisms.

At Jaivik we design programs to remove the micro-organisms from the food particles, which increases the shelf life of the food. The pasteurization plants with low temperature design basically have a shaking pasteurizer which is directly connected to a shaking fluid bed dryer/cooler using ambient superheated steam for pasteurization and sterile filtered air for drying and cooling. The process is controlled by a PLC with data acquisition and analysis.

These plants are designed for products like herbs, seeds, and nuts, e.g., for cinnamon, Parsley, garlic, flake, pistachio nuts, almonds, sunflower seed, dried vegetables etc.

source: Tema process website

Fluid Bed Dryer

Jaivik in partnership with TEMA process BV, specially known for the design and manufacturing of Fluid Bed Systems for drying of minerals, chemicals, food, feed, biomass, etc. The TEMA Fluid Bed can be used for not only drying, but also for cooling, roasting, torrefaction, puffing, blanching, stripping , spices and herbs sterilisation and pasteurisation and calcining.

With a sophisticated PLC, it allows the fluid bed drying system to operate without any form of human intervention. The dryer is controlled with a constant energy balance as the system monitors the air temperature when it exits the dryer.

Key Features:

- Low Energy consumption

- Control of residence time

- Low operating Costs

- Process flexibility

- Integrated Cooling Section in the Dryer